STRESSLITE – PRECAST MANUFACTURER – UK & IRELAND

Case Studies / STRESSLITE – PRECAST MANUFACTURER – UK & IRELAND

PROJECT SUMMARY

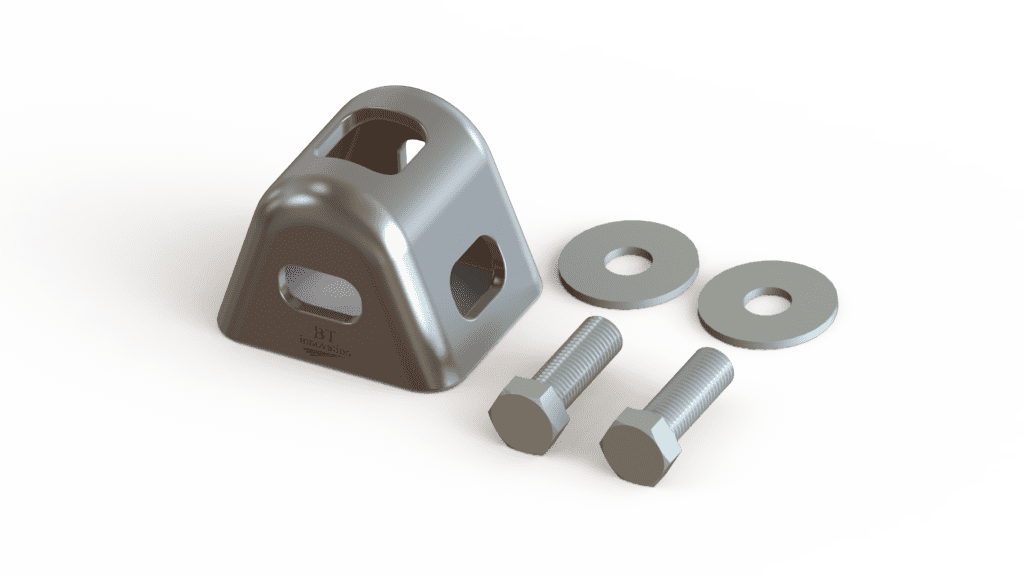

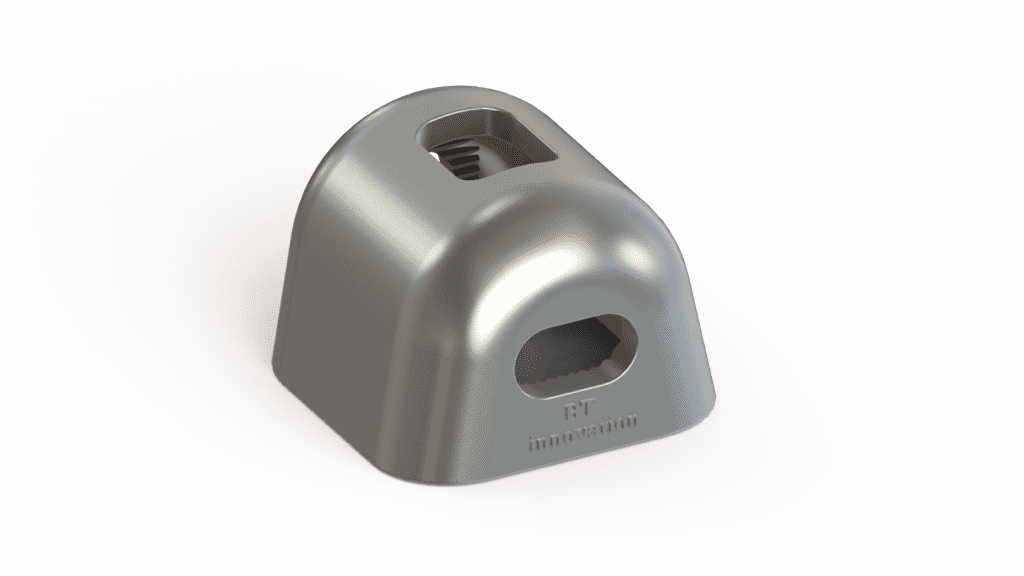

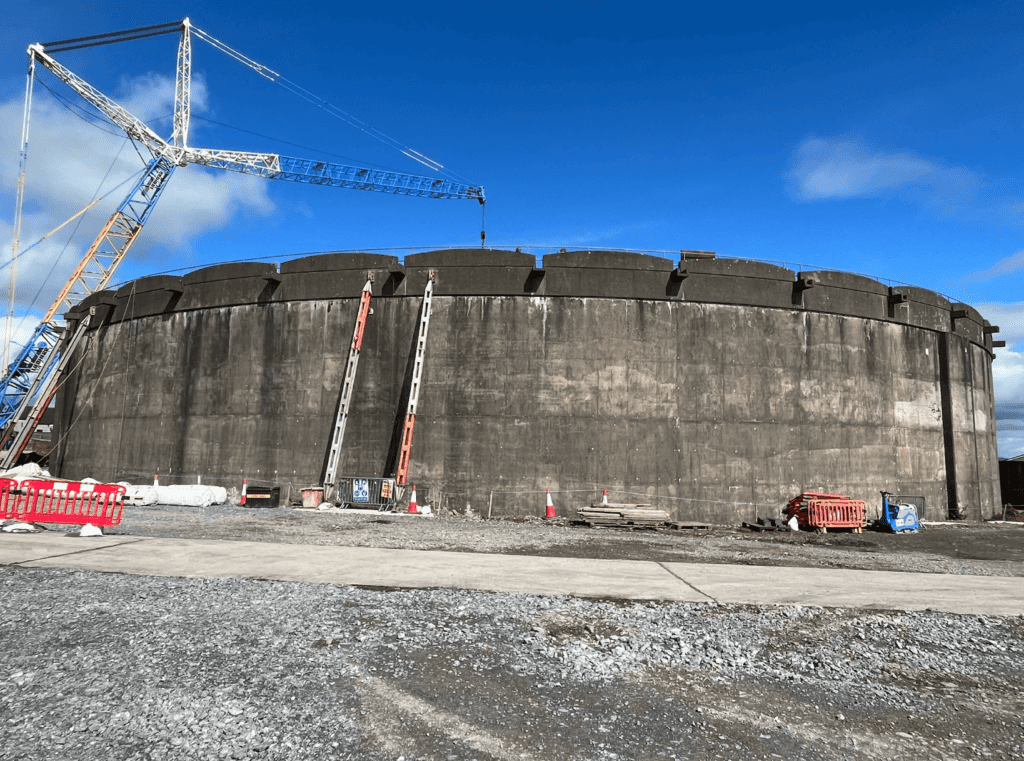

SDG, coupled with SDS who were the head design engineers appointed by LIDL were tasked with providing a full proof and efficient wall connection system for the wall panels being provided to their new Stores. The BT Spannschloss turnbuckle enables efficient and precise assembly and durable connections for precast concrete elements. By using the BT turnbuckle and corresponding connection materials, precast elements can be joined together without using mineral grouting, this therefore results in no curing or down-time due to low temperatures. The Turnbuckle can effectively be used straight away. This lends itself very well to the short construction programmes that are implemented on projects such as Lidl Re-builds.

Share this post