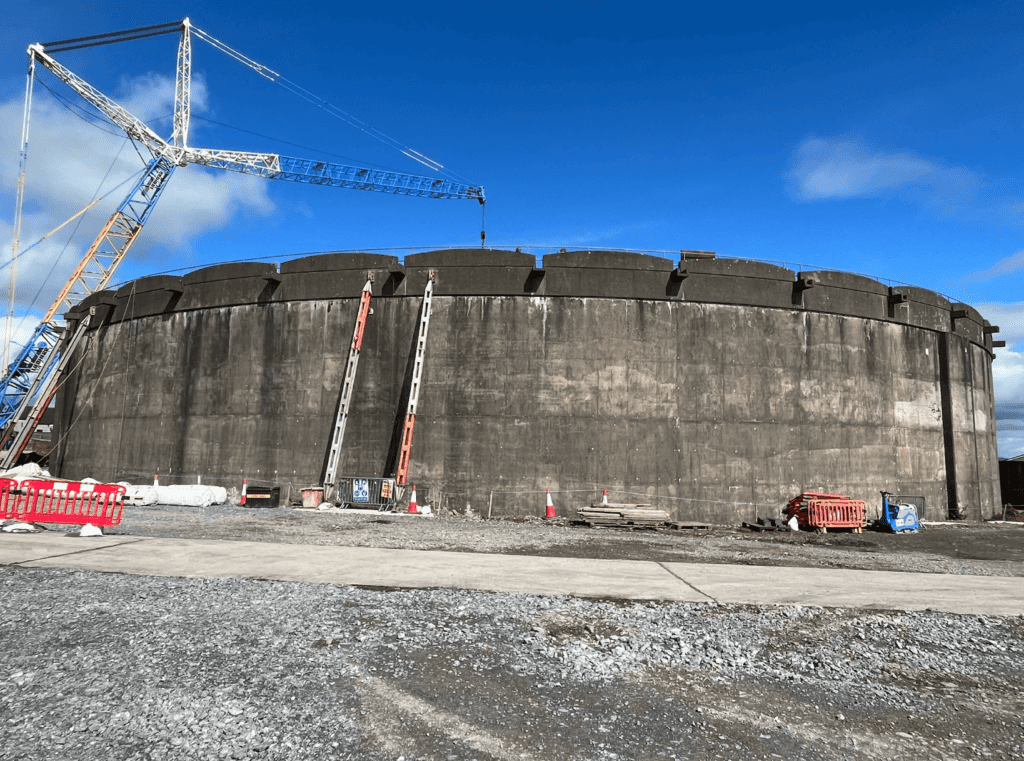

CAUGH HILL WATER TREATMENT PVC Waterstop Joint

Case Studies / CAUGH HILL WATER TREATMENT PVC Waterstop Joint

THE CHALLENGE

Dawson Wam Site Manager Brian Kelly approached SDG for their advice and expertise in developing a bespoke PVC Waterstop joint system. This allowed Dawson Wam to form box outs in the reinforced concrete wall.

The box outs where to allow the passing of steel pipes through the wall and would be subsequently grouted securely to form an integral structurally sound wall. The PVC Waterstop enabled the box outs to be water tight once grouted.

OUR SOLUTION

For this application SDG produced bespoke PVC Waterstop Joint system with six box outs all in one assembly which meant no welding on site and therefore eliminating the potential for leaking.

All joints were welded under factory conditions and tested before dispatching ensuring full homogeneous structurally sound, water tight system.

THE RESULTS

“I had worked with SDG before on special factory fabricated PVC Waterstop Joints so when we looked at the complex arrangement on this project for the box outs and pipe penetrations I decided to engage with them again.

I spoke to Ciaran Donnelly and after a few subsequent drawings emailed back and forth we agreed on the detail. SDG had the assembly on site within 3 days and saved us a lot of time on site with cutting and welding. We were able to lower the assembly into place in one piece with no concerns. I would most definitely engage in this service again

Share this post