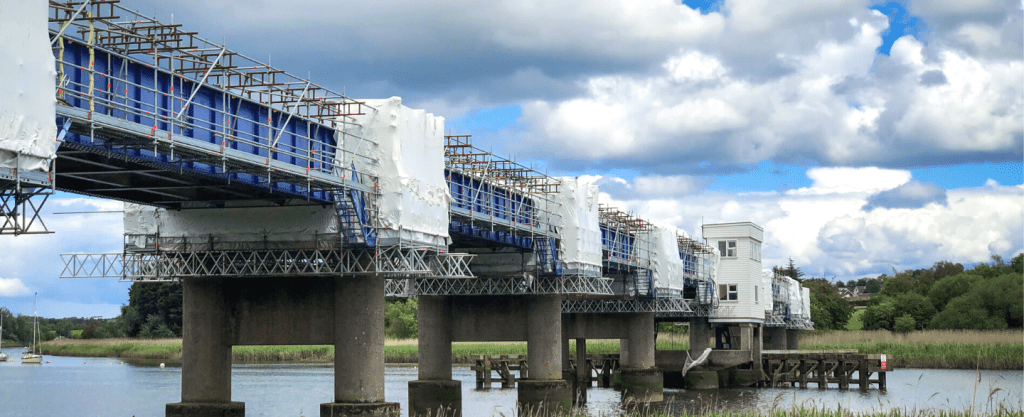

BANN RIVER BRIDGE BEARING REPLACEMENT – COLERAINE TO LONDONDERRY RAIL TRACK

Case Studies / BANN RIVER BRIDGE BEARING REPLACEMENT – COLERAINE TO LONDONDERRY RAIL TRACK

PROJECT SUMMARY

SDG tendered for the design and supply of the replacement bridge bearings, with Main Contractor and long standing partner, FP McCann. To date, this

has been one of our most technically demanding projects to work on, due to the shear level of bespoke design involved in the production of the bearings.

OUR SOLUTION

SDG worked closely with Manufacturer GUMBA based in Germany to design and supply a total of 36 Guided and Free Pot Bearings in accordance with EN 1337-5.

Pot Bearings are a proven bearing type, their industry standing has been achieved through the

combination of a non-reinforced elastomeric bearing (Natural Rubber) confined within a closed steel housing.

With a Pot Bearing, it is possible to transmit high vertical loads on a very small area, in the case of the bearings supplied to the River Bann Project, over 1600kN.

THE RESULTS

Key Benefits Include:

• Pot Bearings have negligible vertical deflection under load

• Pot Bearings have uniform vertical deflection under load

• Pot Bearings have high vertical and horizontal load capacity

• Pot Bearings cause relatively low stress on the bearing seats

For more information on GUMBA Bridge Bearings and projects we have worked on across UK and Ireland, please contact our technical team on +44 (28) 3752 8999 or [email protected]

Share this post