AIRPORT ROAD WEST BRIDGE BEARING REPLACEMENT – BELFAST

Case Studies / AIRPORT ROAD WEST BRIDGE BEARING REPLACEMENT – BELFAST

Main contractor

McGaffin Contracts

Date of Construction

December 2021

Engineer

Doran Consulting

PROJECT SUMMARY

Like all highway structures, bridges have a significant but still limited life span. Bearings offer the structure freedom to move without causing additional stress, but ultimately this stress gets translated to repetitive movements within the bearing that can cause wear over time.

Pot bearings can wear through operation, due to several components within the assembly having variable characteristics which causes a limit on repetitive operational cycles.

THE CHALLENGE

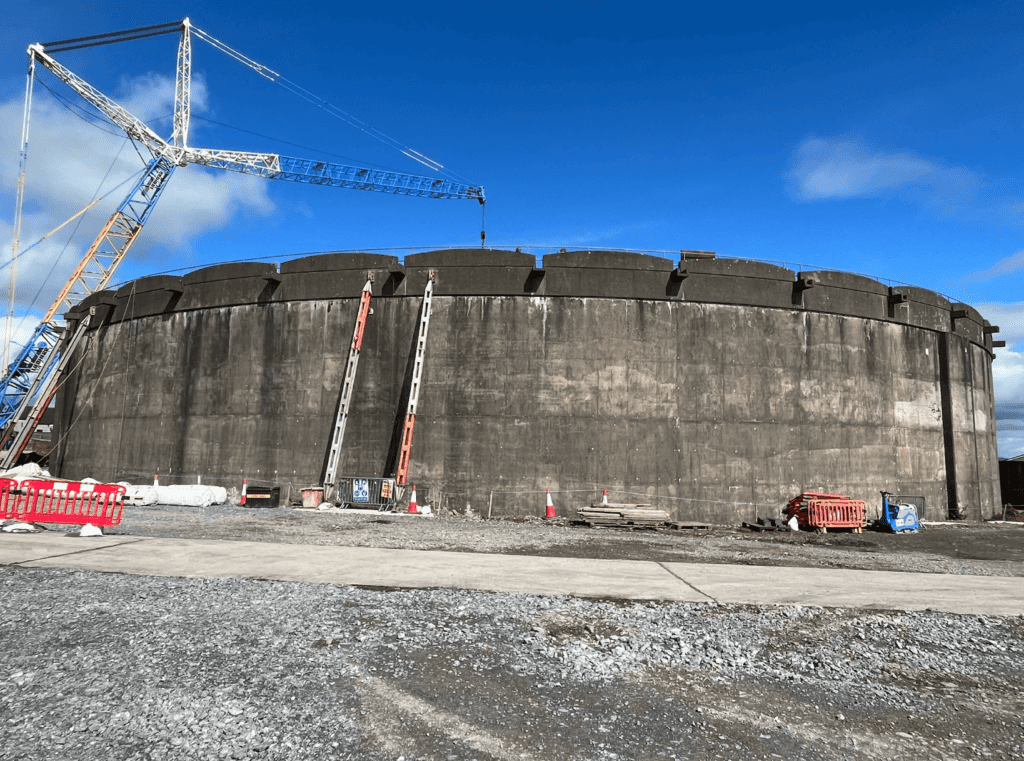

SDG were contacted by McGaffin Contracts in early 2021 requesting a proposal for EN1337 compliant bridge bearings for a large bearing replacement scheme for a critical piece of Belfast Road infrastructure.

We issued an initial price to assist with tender bid for the project and followed up once the main contractor was awarded the project.

Once live, we maintained close communication with the contactor, and consultant engineer (Doran Consulting).

OUR SOLUTION

After reviewing the condition reports on the bridge, SDG worked closely with key partner Gumba, and issued a proposal along with calculations for EN1337-3 compliant replacement ‘Pot Bearings’.

SDG supplied a total of 15 guided pot bearings. Pot bearings are an industry standard for high load transmission,

which is achieved through the combination of a non-reinforced natural rubber elastomer, confined within a closed steel housing.

All GUMBA bridge bearings are in accordance with EN1337-3 regulations (CE certified) and are 100% made in Germany hence are precision engineering to the highest standards.

THE RESULTS

SDG were proud to be key partner throughout the project, and to supply the bearings along with associated design calculations.

A full set of drawings and design calculations were sent for approval to ensure our proposal was in accordance with the specified design parameters. This ensured that there were no issues with site specific dimensions and gave reassurance for installation.

Being an end-to-end construction partner, SDG provided close on site technical back up through our in-house technical team ensuring queries were quickly dealt with by our highly experienced staff.

Share this post